It is undeniable that the industry improves people’s lives with the help of machines capable of automating some processes. We can produce a large number of products at lower cost and labor. That results from three industrial revolutions from the late 18th century steam-powered machines. And we are now in the fourth industrial revolution and aim at creating the smart networking of machines to increase the automation level.

Source: https://www.techradar.com/news/what-is-industry-40-everything-you-need-to-know

Industry 4.0

The term ‘Industry 4.0’ can be used interchangeably with ‘the fourth industrial revolution. Those terms are nowadays discussed popularly between many companies, research centers, and universities…

Industry 4.0 targets to bring digital transformation into manufacturing to improve the production process.

The main idea of Industry 4.0 is about focusing on the communication between machines and integrating IoT so that we can produce an intelligent machine that can self-monitor and make decisions themselves without the interaction of humans.

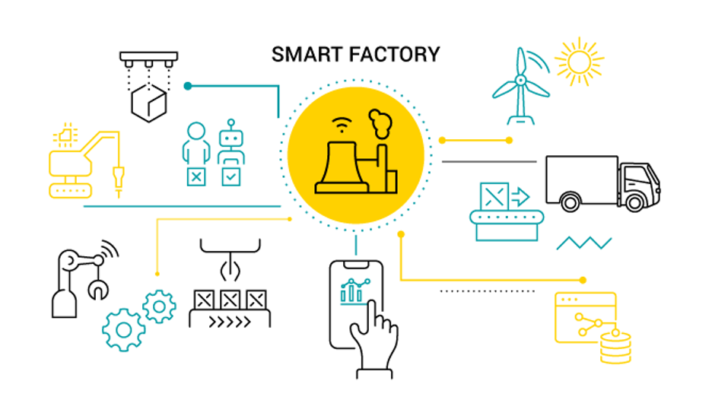

New technologies in Industry 4.0 can be integrated into the manufacturing process which we call smart factories such as:

- Internet of Things

- Cloud computing,

- AI and machine learning

- Edge computing

- Cybersecurity

- Digital twin

Smart factories

Source: https://www.avsystem.com/blog/smart-factory/

Source: https://www.avsystem.com/blog/smart-factory/

We can describe smart factories as highly digitized shop floors. Data is collected and shared between machines. That data can also be used for optimizing the production, finding issues,… Thanks to the development of AI, Data mining, Cloud computing, and IoT, all requirements for building smart factories are now nearly satisfied.

Advantages of smart factories:

- Detect errors immediately: With a smartphone connected to the cloud, manufacturers can monitor the processes.

- Increase productivity and improve quality: Companies can replace the old way of inspecting the business model which is costly and time-consuming, and leverage the AI-powered visual insight.

- Analyzing the data from sensors provides better decision-making. We can increase the automation level, predict where and when the machine needs to have maintenance, optimize the production process and respond to new demands.

Characteristics of a smart factory

- Interconnectivity between machines by the data collected by sensors. This data is shared with other activities in the companies such as enterprise resource planning (ERP).

- Information Technology (IT) and Operational Technology (OT) Integration: The data collected from the factory floor is analyzed for helping manufacturers make decisions, predictions.

- Supply chain: the data is shared with the suppliers for predicting and scheduling the delivery or shipping time

- Custom manufacturing: the production line is not fixed to specific requirements but can change adapt to individual customers’ needs. For example, a company can create a small number of products that differ from their usual products for particular customers.

Technologies of Smart Factories and Industry 4.0

Internet of Things (IoT): a crucial component, where sensors are installed on machines and they have their IP addresses. That allows collecting, mining data, and communicating between machines.

Cloud computing: allows a large amount of data to be stored, shared, analyzed, and reduces cost but still guarantees flexibility. This technology benefits small companies and popularizes smart factories.

AI and machine learning: the information generated from sensors may contain some insights about operations and business processes. Using AI and machine learning techniques will help manufacturers make full use of that sources. For example, data collected from machines can be used to make some predictions about maintenance plans.

Edge computing: provides real-time production operation by allowing some data to be analyzed and proceeded at where it is generated (‘edge’). This also brings some security because the data is near to its source and does not have to be sent somewhere else.

Cybersecurity: manufacturing companies need to pay some attention to the threat of malicious attacks and malware.

In conclusion, building smart factories is the entrance to ‘Industry 4.0’ and opens many opportunities. Automation and data exchange on the factory floor bring real-time visibility and can be seen as fundamental factors to leverage the power of AI and machine learning to make predictions, decisions, and self-optimized of manufacturing processes.

References

https://www.ibm.com/topics/industry-4-0

https://tulip.co/glossary/what-is-a-smart-factory-and-what-it-means-for-you/

https://en.wikipedia.org/wiki/Fourth_Industrial_Revolution#cite_note-Definition-I4.0-25

https://www.techradar.com/news/what-is-industry-40-everything-you-need-to-know